The maximum tonnage of the customer's crane is 500t, which requires a high-current voltage-regulating speed-regulating device, and most equipment on the market cannot meet the requirements.

10THD can be applied to large tonnage cranes and uses patented technology of digital triggering to ensure the passage of 25A~3000A current, while ensuring the durability of the equipment.

Thyristor Digital Drive

10THD adopts advanced automation control technology to achieve safe, reliable and stable operation of the equipment, while carrying a digital platform that makes it easier to understand the operation status of the equipment and ensure efficient and stable production of the production line.

Features

PRODUCT

-

Industrial environment without fear of high temperature and high dustIndustrial environment without fear of high temperature and high dustProduct materials are strictly high temperature testing, and loaded with independent channels of heat dissipation, easily adapt to the high temperature of 60 degrees Celsius.

The control unit is airtight and dustproof, while the circuit board is dustproof and anti-static, so that the product does not fear dust interference. -

Applicable to cranes weighing up to 500 tons with a current of 3000AApplicable to cranes weighing up to 500 tons with a current of 3000A数字触发专利技术,全系列通用,触发可靠、功耗小、寿命长,保证25A~3000A全系列可控硅可靠触发,同时由于触发电路快速和优异的触发特征,保证了控制的可靠性和精度。

-

Modular design reduces the pressure of maintenanceModular design reduces the pressure of maintenanceThe control unit (including circuit boards) is common to the whole series, reducing maintenance difficulty and maintenance time.

The pluggable circuit board makes the maintenance operation easier, while the circuit board adopts gold-plated connectors to avoid poor contact caused by plugging and unplugging, ensuring the reliability of the device. -

Digitalization protects production safetyDigitalization protects production safetyThe equipment status is transmitted to the cloud in real time, which enables real-time online monitoring of production equipment.

The system proactively pushes fault information and maintenance advice to prevent sudden equipment failures and losses before they happen. -

Energy saving and environmental protectionEnergy saving and environmental protectionHoisting mechanism of bridge cranes mostly is operated with high-speed movement. When the lifting mechanism is descending at high speed, the motor is in power generation state, and all the energy generated is fed back to the grid.

The raw materials are all green, low energy consumption and long life components, and environmental factors are fully considered in product design, manufacturing, logistics and transportation.

APPLICATION

Case Study

Thyristor Digital Drive for high current motors

High temperature resistant

In the steelmaking and ironmaking workshops, environmental temperature reaches up to 60 °C. When the air conditioner breaks down, the high temperature causes damage to the equipment and affects production.

10THD can work in the environment of -10℃~60℃, and the selected materials have high temperature resistance, and the equipment has independent channel heat dissipation device to ensure efficient production of the production line.

10THD can work in the environment of -10℃~60℃, and the selected materials have high temperature resistance, and the equipment has independent channel heat dissipation device to ensure efficient production of the production line.

Reduce spare parts management costs

The factory has a lot of hoisting crane equipment, and the cost of purchasing spare parts is high. In order to avoid affecting production, there is a serious backlog of spare parts, and the cost of spare parts management remains high.

10THD consists of a power unit and a control unit, and the control unit (including the circuit board) is common to the whole series, saving spare parts purchase and management costs.

10THD consists of a power unit and a control unit, and the control unit (including the circuit board) is common to the whole series, saving spare parts purchase and management costs.

Frequent overcurrent alarms

Customer found that the control system was abnormal, and 10THD had frequent overcurrent alarms, and it was necessary to find out the cause of abnormality. Through digital system analysis, overload information and speed reduction will appear when an overcurrent alarm occurs. It is speculated that there is an object blocking the railway and affecting actual operation. After checking the crane railway, it was indeed found that there was sludge, and the system returned to normal after cleaning the foreign object on the railway.

Specifications

Technical

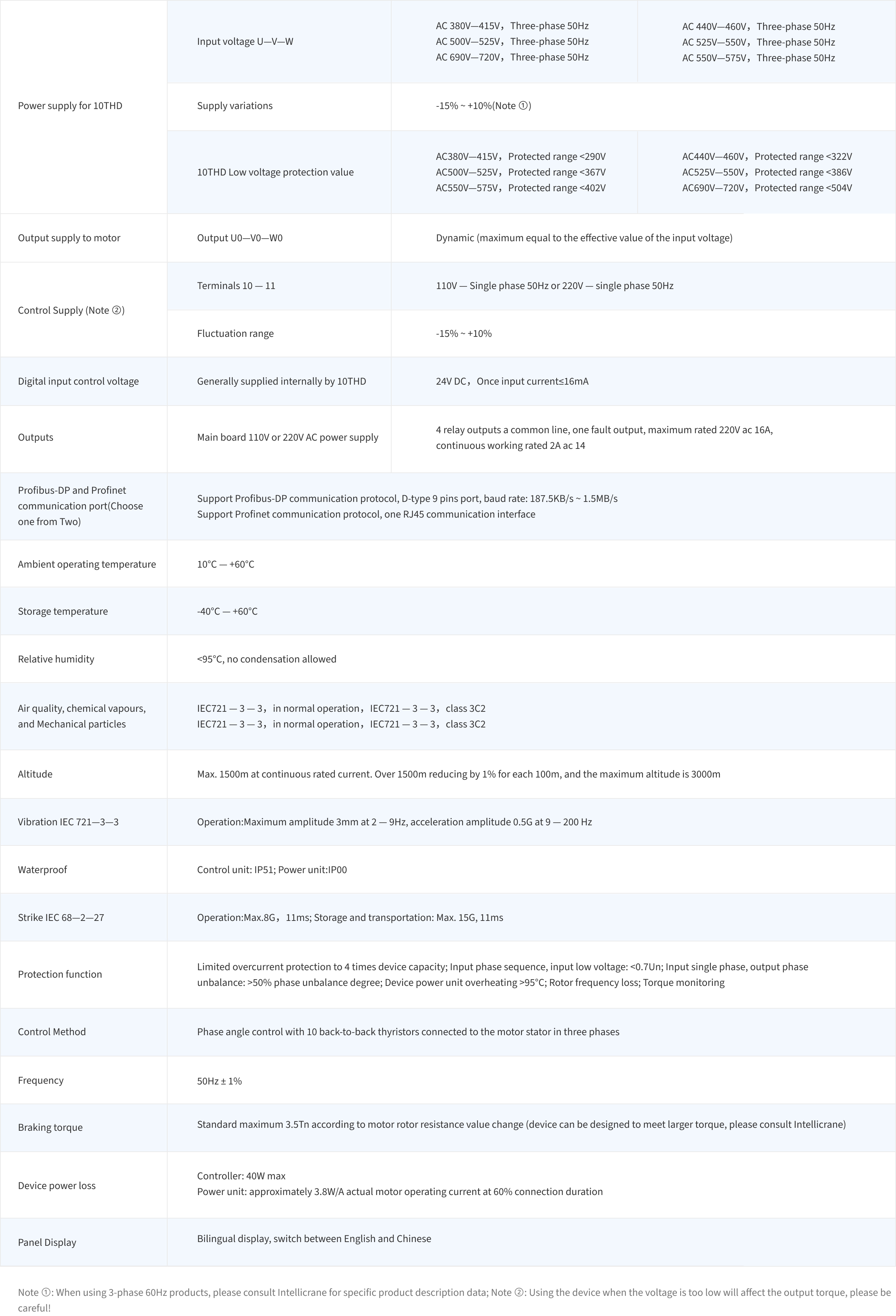

|

Power supply for 10THD

|

Input voltage U—V—W

|

AC 380V—415V,Three-phase 50Hz

AC 500V—525V,Three-phase 50Hz AC 690V—720V,Three-phase 50Hz |

AC 440V—460V,Three-phase 50Hz

AC 525V—550V,Three-phase 50Hz AC 550V—575V,Three-phase 50Hz |

|

Supply variations

|

-15% ~ +10%(Note ①)

|

||

|

10THD Low voltage protection value

|

AC380V—415V,Protected range < 290V

AC500V—525V,Protected range< 367V AC550V—575V,Protected range< 402V |

AC440V—460V,Protected range< 322V

AC525V—550V,Protected range< 386V AC690V—720V,Protected range< 504V |

|

|

Output supply to motor

|

Output U0—V0—W0

|

Dynamic (maximum equal to the effective value of the input voltage)

|

|

|

Control Supply (Note ②)

|

Terminals 10 — 11

|

110V — Single phase 50Hz or 220V — single phase 50Hz

|

|

|

Fluctuation range

|

-15%~+10%

|

||

|

Digital input control voltage

|

Generally supplied internally by 10THD

|

24V DC,Once input current≤16mA

|

|

|

Outputs

|

Main board 110V or 220V AC power supply

|

4 relay outputs a common line, one fault output, maximum rated 220V ac 16A, continuous working rated 2A ac 14

|

|

|

Profibus-DP and Profinet communication port

(Choose one from Two) |

Support Profibus-DP communication protocol, D-type 9 pins port, baud rate: 187.5KB/s ~ 1.5MB/s

Support Profinet communication protocol, one RJ45 communication interface |

||

|

Ambient operating temperature

|

10°C — +60°C

|

||

|

Storage temperature

|

-40°C — +60°C

|

||

|

Relative humidity

|

< 95°C, no condensation allowed

|

||

|

Air quality, chemical vapours, and Mechanical particles

|

IEC721 — 3 — 3,in normal operation,IEC721 — 3 — 3,class 3C2

IEC721 — 3 — 3,in normal operation,IEC721 — 3 — 3,class 3C2 |

||

|

Altitude

|

Max. 1500m at continuous rated current.

Over 1500m reducing by 1% for each 100m, and the maximum altitude is 3000m. |

||

|

Vibration IEC 721—3—3

|

Operation:Maximum amplitude 3mm at 2 — 9Hz, acceleration amplitude 0.5G at 9 — 200 Hz.

|

||

|

Waterproof

|

Control unit: IP51; Power unit:IP00

|

||

|

Strike IEC 68—2—27

|

Operation:Max.8G,11ms;

Storage and transportation: Max. 15G, 11ms; |

||

|

Protection function

|

Limited overcurrent protection to 4 times device capacity;

Input phase sequence, input low voltage: < 0.7Un; Input single phase, output phase unbalance: >50% phase unbalance degree; Device power unit overheating >95°C; Rotor frequency loss; Torque monitoring |

||

|

Control Method

|

Phase angle control with 10 back-to-back thyristors connected to the motor stator in three phases

|

||

|

Frequency

|

50Hz±1%

|

||

|

Braking torque

|

Standard maximum 3.5Tn according to motor rotor resistance value change (device can be designed to meet larger torque, please consult Intellicrane)

|

||

|

Device power loss

|

Controller: 40W max.

Power unit: approximately 3.8W/A actual motor operating current at 60% connection duration |

||

|

Panel Display

|

Bilingual display, switch between English and Chinese

|

||

Note ①: When using 3-phase 60Hz products, please consult Intellicrane for specific product description data;

Note ②: Using the device when the voltage is too low will affect the output torque, please be careful!

Note ②: Using the device when the voltage is too low will affect the output torque, please be careful!

-

Solutions

-

Products

-

About us

-

Contact Us

sales1@intellicrane.com-

WeChat Official Account

-

Customer Service Account

-

Copyright © 2023 盈泰利华. All Rights Reserved. 粤ICP备10203972号-2