The full bucket rate of the crane bucket is the key point to ensure high production efficiency, but in real life, there is a shortage of drivers who grab full buckets every time. In addition, it is often faced with the problem of wire rope falling off. In order to make production more efficient, INTELLICRANE has worked hard on grabbing full buckets.

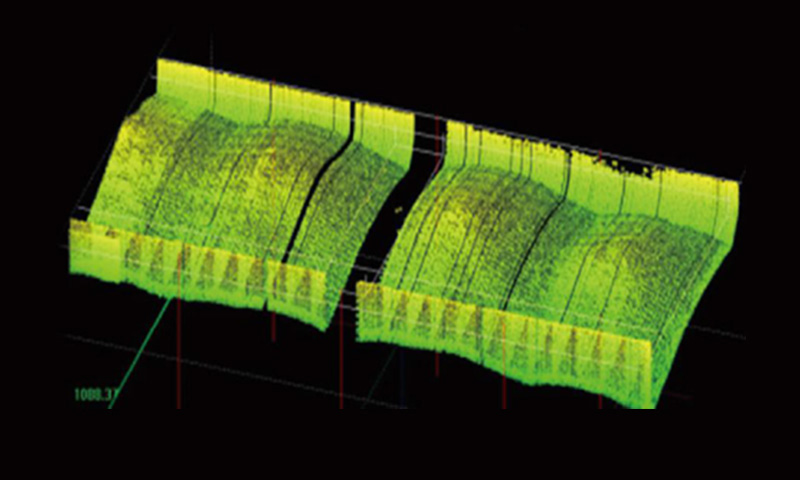

Material identification is faced with the problem of harsh working environment, a lot of dust in the air and water accumulation in the silo. Conventional imaging technology cannot penetrate such "loose dust mist". INTELLICRANE applies pulsed high-frequency electromagnetic wave technology. Pulsed high-frequency electromagnetic waves can easily penetrate high-reflective media such as dense mineral powder and water vapor for three-dimensional scanning of material piles, providing the best pick-up point for the driver, allowing the driver to have a whole perspective. After finding the best pick-up point, we need to ensure the following three points.

- Anti-Sway Control System

- Bucket Crane Full Rate

- Wire Anti-shedding Groove

-

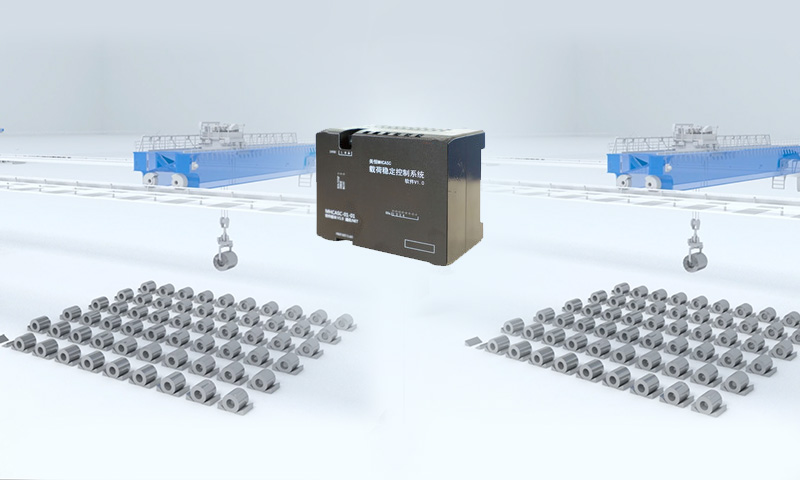

The grab of the crane will shake during the movement. At this time, the driver can adjust the speed to eliminate the swing, but it still cannot be completely avoided.

-

Anti-Sway Control System

INTELLICRANE's self-developed Anti-Sway Control System only needs to change the original lifting and translating mechanisms into inverter bus control, and input the algorithm parameters at one time, which can reduce the swing range by 95%, and make the swing range <50mm after stationary.

-

When the grab bucket falls on the slope of the material pile, the difficulty of grabbing the full bucket will rise linearly.

-

Intelligent Grabbing Model

Intellicrane develops intelligent grabbing model. The clamshell backet completely sink at the maximum opening and closing angle using the gravity of the bucket. Grabbing model controls speed and torque of the backet, so that the wire rope of grab crane bucket is is on the right position of tightness and slackness to ensure the clamshell backet is full.

-

Wire rope is soft and may be loosen and fall out of groove in the process of grabbing materials.

-

Electronic Slot Monitoring Unit

By real-time monitoring of grab height, weight, current and other parameters, when the grab is on the ground, the wire rope of the opening and closing mechanism is guaranteed to have an upward moment, so as to prevent the wire rope of the grab from being in a "slack" state, thereby preventing the wire rope from falling out of the groove.

When lifting materials, the electronic monitoring unit monitors the vertical state of the wire rope to prevent crooked pulling and oblique lifting. The electronic groove monitoring unit will identify whether the wire rope is out of groove and generate an alarm to ensure safe operation.

-

The grab of the crane will shake during the movement. At this time, the driver can adjust the speed to eliminate the swing, but it still cannot be completely avoided.

-

Anti-Sway Control System

INTELLICRANE's self-developed Anti-Sway Control System only needs to change the original lifting and translating mechanisms into inverter bus control, and input the algorithm parameters at one time, which can reduce the swing range by 95%, and make the swing range <50mm after stationary.

-

When the grab bucket falls on the slope of the material pile, the difficulty of grabbing the full bucket will rise linearly.

-

Intelligent Grabbing Model

Intellicrane develops intelligent grabbing model. The clamshell backet completely sink at the maximum opening and closing angle using the gravity of the bucket. Grabbing model controls speed and torque of the backet, so that the wire rope of grab crane bucket is is on the right position of tightness and slackness to ensure the clamshell backet is full.

-

Wire rope is soft and may be loosen and fall out of groove in the process of grabbing materials.

-

Electronic Slot Monitoring Unit

By real-time monitoring of grab height, weight, current and other parameters, when the grab is on the ground, the wire rope of the opening and closing mechanism is guaranteed to have an upward moment, so as to prevent the wire rope of the grab from being in a "slack" state, thereby preventing the wire rope from falling out of the groove.

When lifting materials, the electronic monitoring unit monitors the vertical state of the wire rope to prevent crooked pulling and oblique lifting. The electronic groove monitoring unit will identify whether the wire rope is out of groove and generate an alarm to ensure safe operation.

-

Solutions

-

Products

-

About us

-

Contact Us

sales1@intellicrane.com-

WeChat Official Account

-

Customer Service Account

-