INTELLICRANE conducts 3D modeling of the real world, accesses real-time factory data, interfaces with the MES system, obtains the information status of personnel, equipment, materials, production and the environment in real time, and helps the system make the best decision. Utilize the intelligent three-level closed-loop command system to realize the efficient operation of the logistics system.

- Intelligent Scheduling System

- Intelligent Work Order Arrangement System

- Intelligent Equipment Scheduling System

-

The intelligent scheduling system combines the production procedure, process, BOM and other information, automatically connects the order and process information of the workshop, production line, and station, and coordinates the realization of automatic scheduling or provides decision support for personnel.

-

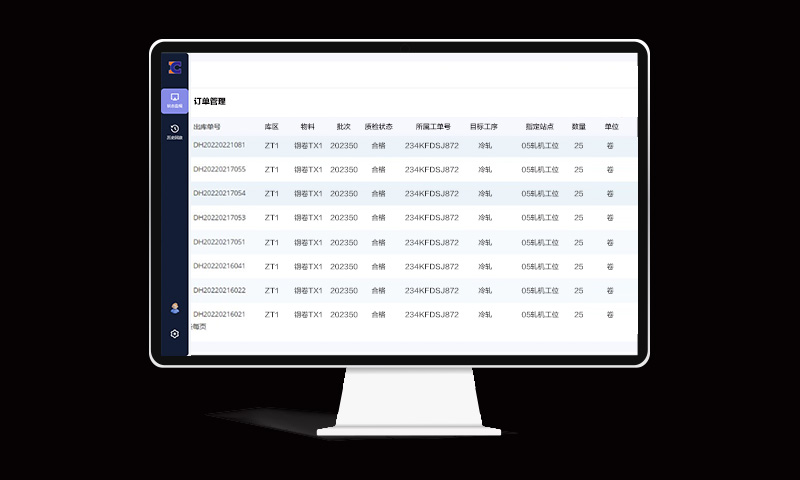

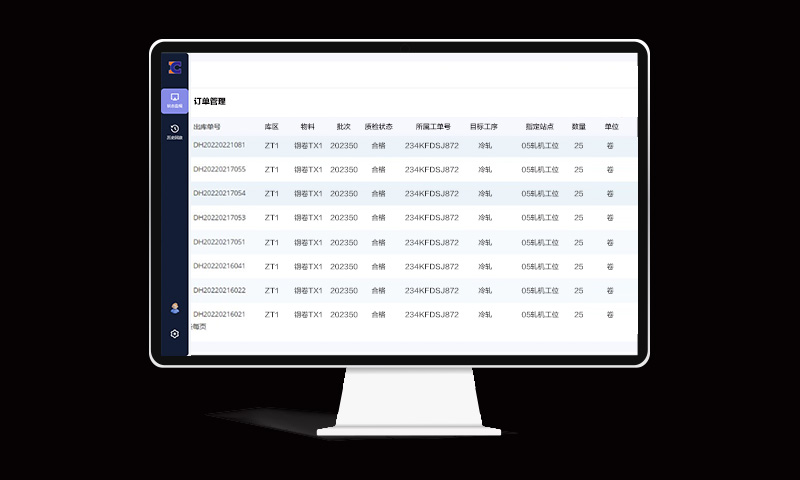

The intelligent work order scheduling system will combine information from work order scheduling, order types, material batches, storage areas, production beats, line side vacancies, business priorities and other information to reasonably arrange the order inventory and demand Arrangement in sequence, and form a dispatching system for cargo handling requirements.

-

Based on the order handling requirements, combined with the site, warehouse storage, equipment, path and capacity, and according to the algorithm coordination calculation, the equipment scheduling system intelligently arranges the execution of handling tasks by the equipment in the field, avoiding conflicts and obstacles in the field, and making adaptive adjustments to the dynamic changes of abnormalities, congestion, equilibrium, site capacity, etc.

-

The intelligent scheduling system combines the production procedure, process, BOM and other information, automatically connects the order and process information of the workshop, production line, and station, and coordinates the realization of automatic scheduling or provides decision support for personnel.

-

The intelligent work order scheduling system will combine information from work order scheduling, order types, material batches, storage areas, production beats, line side vacancies, business priorities and other information to reasonably arrange the order inventory and demand Arrangement in sequence, and form a dispatching system for cargo handling requirements.

-

Based on the order handling requirements, combined with the site, warehouse storage, equipment, path and capacity, and according to the algorithm coordination calculation, the equipment scheduling system intelligently arranges the execution of handling tasks by the equipment in the field, avoiding conflicts and obstacles in the field, and making adaptive adjustments to the dynamic changes of abnormalities, congestion, equilibrium, site capacity, etc.

-

Solutions

-

Products

-

About us

-

Contact Us

sales1@intellicrane.com-

WeChat Official Account

-

Customer Service Account

-