-

PositionAIOT solution provider with positioning technology

PositionAIOT solution provider with positioning technology

- Electrical Substation

- Sewage Chemical Plant

- Iron and Steel Metallurgical Plant

- Logistics Workshop

-

Customer Pain Point

The high-voltage work area of the substation is a typical high-risk work area, and major accidents are prone to occur if you don't pay attention, so the location of the workers in the factory area requires extremely high accuracy.

-

Solution

Using the three platforms of UWB Internet of Things terminal equipment, spatial positioning engine, and business system, Unicteco uses high-precision algorithms to accurately calculate the location information of tags, and realizes personnel positioning with an accuracy of ±30 cm, combined with the integrated intelligent monitoring platform of substations Real-time location display and other safety prevention and control functions improve the safety management and control capabilities and digital management level of the substation factory area.

-

Customer Pain Point

In the inspection process, there is a lack of a comprehensive supervision process and a lack of data-based supervision methods: ① cannot return to the historical work, alarms and accidents in the lake; ② cannot fully supervise all personnel; ③ cannot supervise anytime and anywhere; ④ for external There are also problems such as difficult supervision and inconvenient recording of workers and visitors.

-

Solution

With UWB technology as the core, Unicteco provides centimeter-level high-precision positioning services for sewage chemical plants. By setting up an access control system in the chemical plant, deploying UWB positioning base stations in the factory area, operators, inspection personnel and visitors wear positioning tags, adopting multi-dimensional positioning of 0-dimensional presence detection, 1-dimensional linear trajectory positioning, and 2-dimensional regional plane positioning fusion mode, accurately locate the real-time position of personnel, combined with 20/ 3D map, realize the visual presentation of the personnel position in the substation, and combine the track playback, electronic attendance electronic fence, intelligent inspection, video linkage, one-key help and other business function systems to greatly improve the chemical industry plant safety management efficiency.

-

Customer Pain Point

As an important handling equipment in the cattle production workshop, the crane is crucial to ensure its safe and reliable continuous operation; the busy work brings many challenges to the operation of the equipment, and the collision between the cranes is a typical accident, not only It will cause damage to the equipment of the unit and even endanger personal safety.

-

Solution

The project uses UWB positioning technology to deploy a base station at both ends of the factory area, and deploy a tag on the crane mechanism and trolley mechanism of each crane to realize the positioning of the crane and trolley of each crane on the track in real time. Monitor the distance and motion status between the cranes, and the human-computer interaction panel will send out voice and light prompts in time to remind the driver to pay attention, and at the same time slow down or stop under the control of PLC.

-

Customer Pain Point

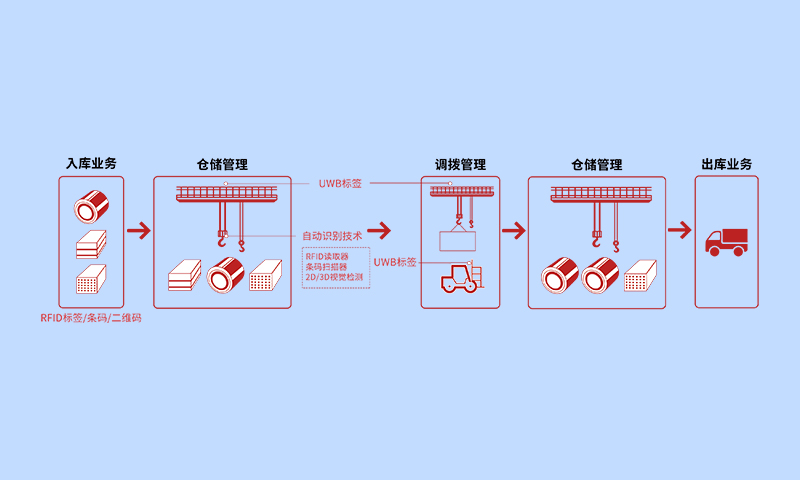

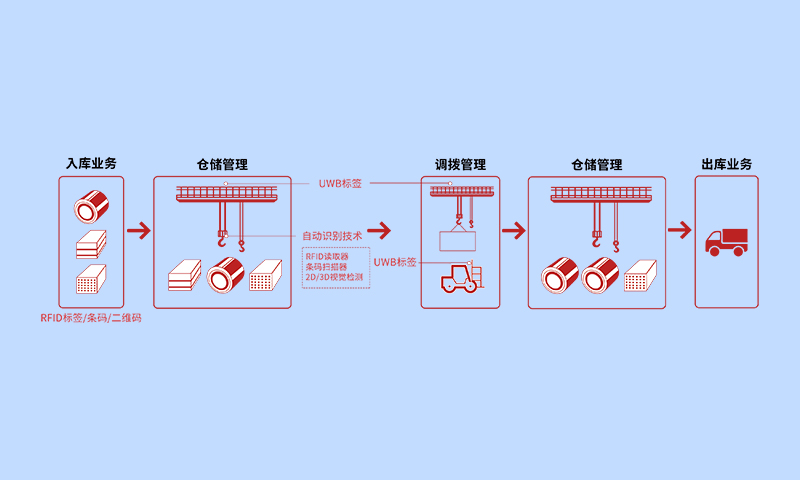

In order to achieve efficient production in factories, there is a lot of pressure on material storage and information transmission of material flow. The flow of material boxes between workshops and the confirmation of the location of materials after they enter the workshop require a large amount of information records. Once mistakes are made, it will lead to difficulties in finding materials, difficulty in scheduling goods, and reduced production efficiency.

-

Solution

Facing the problem of uncontrollable and disjointed flow information of material boxes in various workshops, Unicteco adopted a solution combining RFID and UWB technology, and installed RFID readers and UWB positioning base stations in each workshop. Cargo boxes are fitted with RFID tags. Through the location service platform, real-time control of the running track of each frame material in the entire factory area and docking with the business system, real-time control of specific information such as product location, inventory, transfer, etc., to achieve data and intelligence, and then improve production efficiency.

-

Customer Pain Point

The high-voltage work area of the substation is a typical high-risk work area, and major accidents are prone to occur if you don't pay attention, so the location of the workers in the factory area requires extremely high accuracy.

-

Solution

Using the three platforms of UWB Internet of Things terminal equipment, spatial positioning engine, and business system, Unicteco uses high-precision algorithms to accurately calculate the location information of tags, and realizes personnel positioning with an accuracy of ±30 cm, combined with the integrated intelligent monitoring platform of substations Real-time location display and other safety prevention and control functions improve the safety management and control capabilities and digital management level of the substation factory area.

-

Customer Pain Point

In the inspection process, there is a lack of a comprehensive supervision process and a lack of data-based supervision methods: ① cannot return to the historical work, alarms and accidents in the lake; ② cannot fully supervise all personnel; ③ cannot supervise anytime and anywhere; ④ for external There are also problems such as difficult supervision and inconvenient recording of workers and visitors.

-

Solution

With UWB technology as the core, Unicteco provides centimeter-level high-precision positioning services for sewage chemical plants. By setting up an access control system in the chemical plant, deploying UWB positioning base stations in the factory area, operators, inspection personnel and visitors wear positioning tags, adopting multi-dimensional positioning of 0-dimensional presence detection, 1-dimensional linear trajectory positioning, and 2-dimensional regional plane positioning fusion mode, accurately locate the real-time position of personnel, combined with 20/ 3D map, realize the visual presentation of the personnel position in the substation, and combine the track playback, electronic attendance electronic fence, intelligent inspection, video linkage, one-key help and other business function systems to greatly improve the chemical industry plant safety management efficiency.

-

Customer Pain Point

As an important handling equipment in the cattle production workshop, the crane is crucial to ensure its safe and reliable continuous operation; the busy work brings many challenges to the operation of the equipment, and the collision between the cranes is a typical accident, not only It will cause damage to the equipment of the unit and even endanger personal safety.

-

Solution

The project uses UWB positioning technology to deploy a base station at both ends of the factory area, and deploy a tag on the crane mechanism and trolley mechanism of each crane to realize the positioning of the crane and trolley of each crane on the track in real time. Monitor the distance and motion status between the cranes, and the human-computer interaction panel will send out voice and light prompts in time to remind the driver to pay attention, and at the same time slow down or stop under the control of PLC.

-

Customer Pain Point

In order to achieve efficient production in factories, there is a lot of pressure on material storage and information transmission of material flow. The flow of material boxes between workshops and the confirmation of the location of materials after they enter the workshop require a large amount of information records. Once mistakes are made, it will lead to difficulties in finding materials, difficulty in scheduling goods, and reduced production efficiency.

-

Solution

Facing the problem of uncontrollable and disjointed flow information of material boxes in various workshops, Unicteco adopted a solution combining RFID and UWB technology, and installed RFID readers and UWB positioning base stations in each workshop. Cargo boxes are fitted with RFID tags. Through the location service platform, real-time control of the running track of each frame material in the entire factory area and docking with the business system, real-time control of specific information such as product location, inventory, transfer, etc., to achieve data and intelligence, and then improve production efficiency.

-

Solutions

-

Products

-

About us

-

Contact Us

sales1@intellicrane.com-

WeChat Official Account

-

Customer Service Account

-