However, the operating environment of bulk warehouses in iron and steel factories is full of dust and water vapor. Human eyes and ordinary cameras cannot identify the location of materials and trucks, which not only leads to low efficiency of electromagnetic crane operations, but also poses a great threat to the safety of personnel and equipment.

To realize automatic lifting of bulk materials, data collection, algorithm identification and intelligent control need to be solved.

- Intelligent Sensor

- Patented Algorithm

- Crane Control System

-

Intelligent Sensor

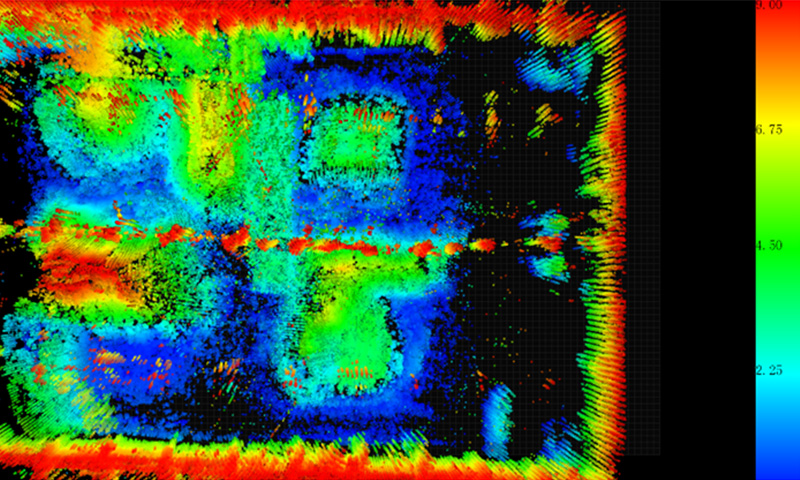

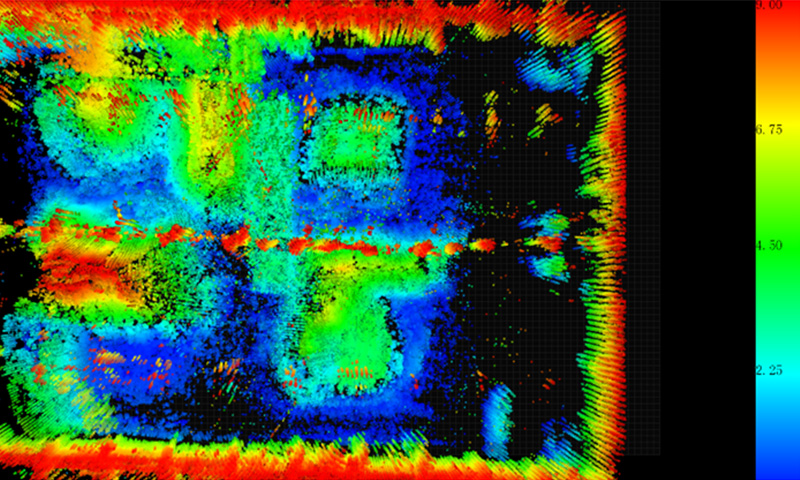

2D cameras have limitations for material information collection, and cannot collect volume, depth and other information. The 3D LIDAR camera, on the other hand, can penetrate the dense dust and water vapor in the air, and can extract 2D and 3D data information, which is more complete and three-dimensional.

-

Major Equipment

1. Dome Camera, which can automatically track the crane hook

2. Bullet Camera, which conducts all-round video surveillance of cranes, trucks, and personnel operating areas.

-

2D-AI Vision Fused with 3D Point Cloud Technology

INTELLICRANE applies 2D AI vision technology to identify the color, type, location of bulk materials, and combines 3D point cloud technology to identify the height, surface area, and volume of bulk materials.

-

Bulk Material

Intellicrane can intelligently image the contours of the material pool and calculate the optimal pick-up position for efficient material gripping.

-

Transport Wehicle

INTELLICRANE's unique point cloud imaging recognition can not only identify the orientation, front and body of the vehicle, but also accurately identify the coordinates and skew of the vehicle body to ensure the safety and efficiency of loading.

-

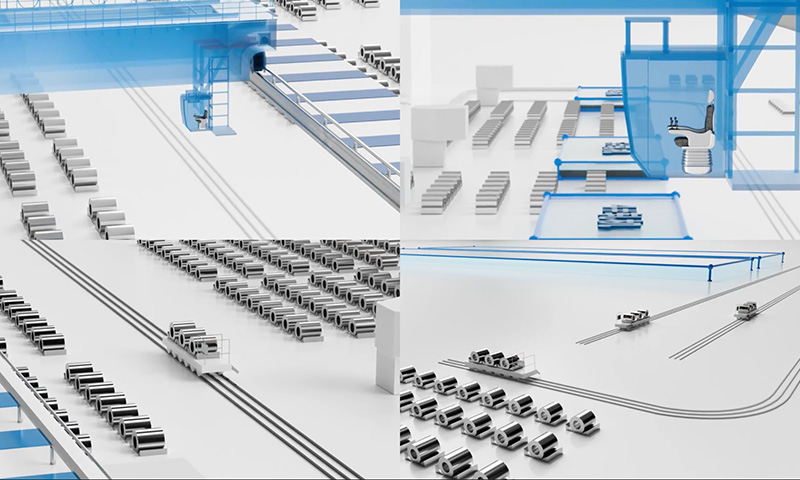

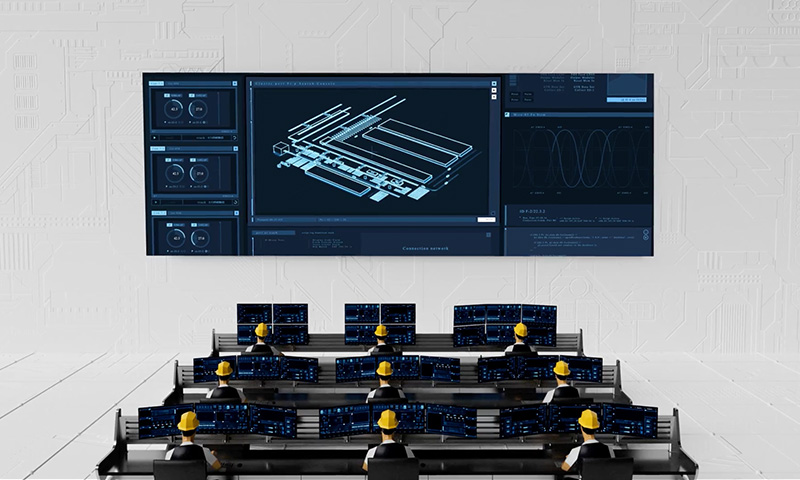

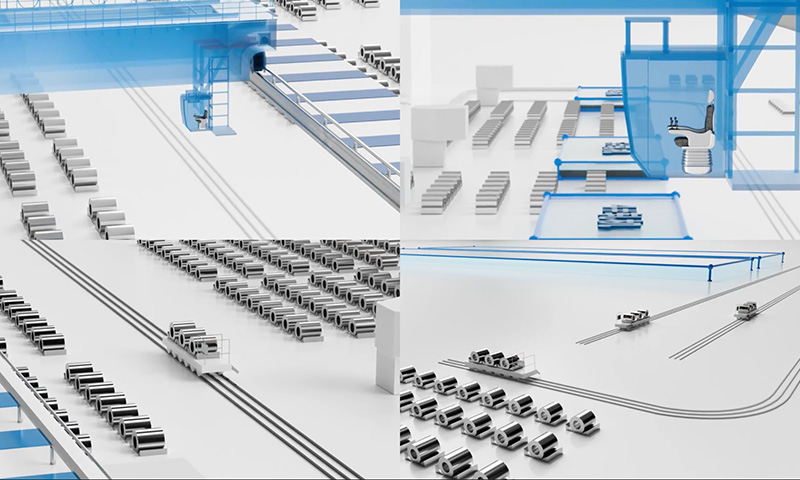

According to the production target, the crane can be operated in three modes: automatic, remote manual and local manual.

-

Fully Automatic

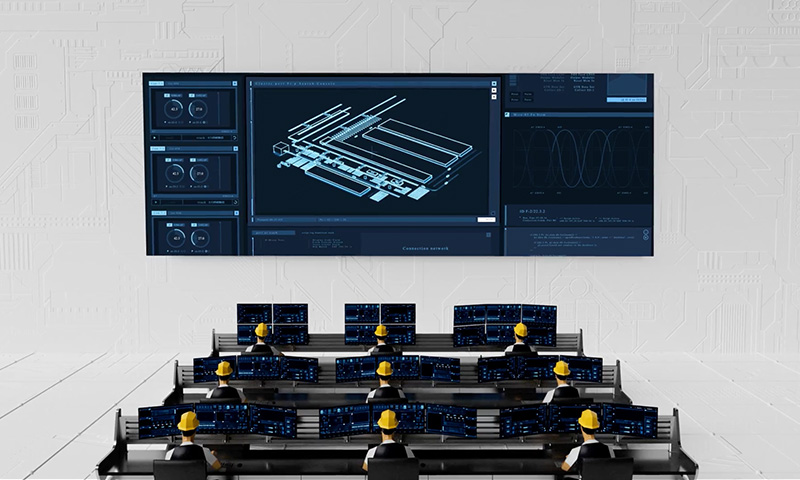

The central console plays the role of core control, issuing crane automatic unmanned control commands, and centrally managing access control and ground video.

-

Remote Manual

The remote/local selection switch is configured on the crane, and when it is switched to remote, the operator operates on the remote console in the central control room combined with on-site video monitoring.

-

Local Manual

The remote/local selection switch is configured on the crane, and when switching to local, the operator operates the crane in the driver's cab.

-

Intelligent Sensor

2D cameras have limitations for material information collection, and cannot collect volume, depth and other information. The 3D LIDAR camera, on the other hand, can penetrate the dense dust and water vapor in the air, and can extract 2D and 3D data information, which is more complete and three-dimensional.

-

Major Equipment

1. Dome Camera, which can automatically track the crane hook

2. Bullet Camera, which conducts all-round video surveillance of cranes, trucks, and personnel operating areas.

-

2D-AI Vision Fused with 3D Point Cloud Technology

INTELLICRANE applies 2D AI vision technology to identify the color, type, location of bulk materials, and combines 3D point cloud technology to identify the height, surface area, and volume of bulk materials.

-

Bulk Material

Intellicrane can intelligently image the contours of the material pool and calculate the optimal pick-up position for efficient material gripping.

-

Transport Wehicle

INTELLICRANE's unique point cloud imaging recognition can not only identify the orientation, front and body of the vehicle, but also accurately identify the coordinates and skew of the vehicle body to ensure the safety and efficiency of loading.

-

According to the production target, the crane can be operated in three modes: automatic, remote manual and local manual.

-

Fully Automatic

The central console plays the role of core control, issuing crane automatic unmanned control commands, and centrally managing access control and ground video.

-

Remote Manual

The remote/local selection switch is configured on the crane, and when it is switched to remote, the operator operates on the remote console in the central control room combined with on-site video monitoring.

-

Local Manual

The remote/local selection switch is configured on the crane, and when switching to local, the operator operates the crane in the driver's cab.

-

Solutions

-

Products

-

About us

-

Contact Us

sales1@intellicrane.com-

WeChat Official Account

-

Customer Service Account

-