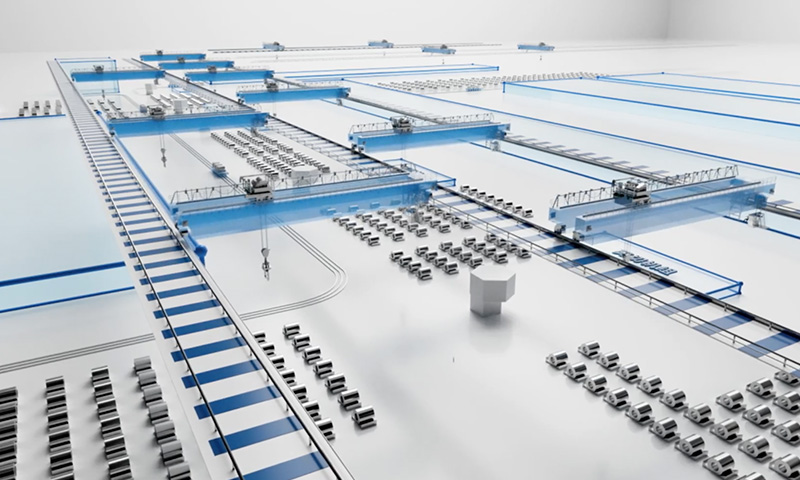

Different factories have different production scale, production goals and digitalization degree, and the solutions for their intelligent upgrade should be determined by the needs, generally focusing on and upgrading intelligent manufacturing and digital management. The digital intelligence brain, which plays a central role, needs to understand the work of the whole process and continuously learn to optimize in order to adapt to complex production and logistics scenarios.

- Logistics Management System

- Crane Automation Control System

- Digital Maintenance System

- Ground System

-

Logistics management of the production workshop is more complicated than that of the warehouse. The trigger of handling is highly correlated with each production process section and there is a strong correlation between process sections. Its intelligent management requires understanding the whole flow of the production process and collecting data from each node as much as possible in order to issue the right instructions.

-

Solution

Digital twin platform, intelligent scheduling system, intelligent work order arrangement system, intelligent equipment scheduling and conflict resolution system, etc.

-

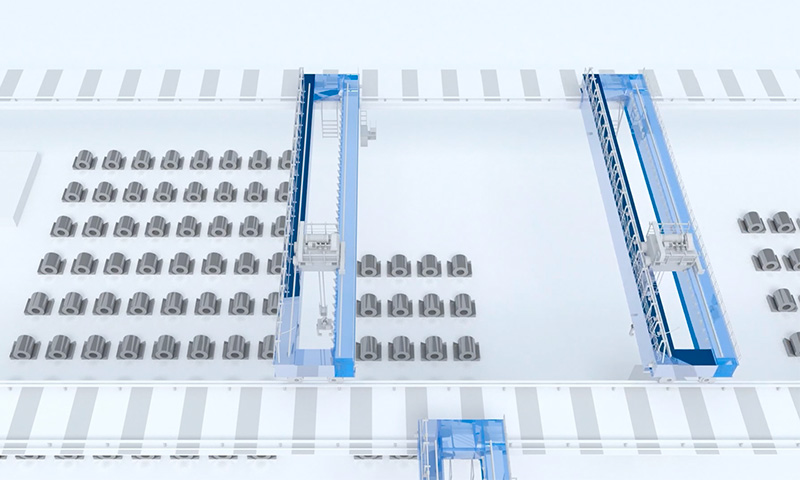

As the main transportation tool in the production workshop, the crane takes over the instructions of the logistics management system.

The safe, stable and efficient operation of the traveling crane enables the production capacity to meet the established requirements. -

Solution

Electric control system, Automatic control system, 3D Vision Assist System for Coil Hook, Anti-Sway Control System, Crane Driving Assistant System, Crane Positioning System etc.

-

The digitalization of maintenance can reduce the risk of factory sudden shutdown. It only needs to monitor equipment data in real time On the basis of equipment interconnection, it monitors equipment data in real time, carries the maintenance knowledge and service of industrial equipment.

-

Solution

Crane health management platform, remote service center, predictive maintenance system, etc.

-

The production environment of the factory is complex and there are high safety risks. The ground system can transfer most of the work to the centralized control center to reduce dangerous positions and avoid frequent walking on the ground.

-

Solution

3D visualization security management platform, etc.

-

Logistics management of the production workshop is more complicated than that of the warehouse. The trigger of handling is highly correlated with each production process section and there is a strong correlation between process sections. Its intelligent management requires understanding the whole flow of the production process and collecting data from each node as much as possible in order to issue the right instructions.

-

Solution

Digital twin platform, intelligent scheduling system, intelligent work order arrangement system, intelligent equipment scheduling and conflict resolution system, etc.

-

As the main transportation tool in the production workshop, the crane takes over the instructions of the logistics management system.

The safe, stable and efficient operation of the traveling crane enables the production capacity to meet the established requirements. -

Solution

Electric control system, Automatic control system, 3D Vision Assist System for Coil Hook, Anti-Sway Control System, Crane Driving Assistant System, Crane Positioning System etc.

-

The digitalization of maintenance can reduce the risk of factory sudden shutdown. It only needs to monitor equipment data in real time On the basis of equipment interconnection, it monitors equipment data in real time, carries the maintenance knowledge and service of industrial equipment.

-

Solution

Crane health management platform, remote service center, predictive maintenance system, etc.

-

The production environment of the factory is complex and there are high safety risks. The ground system can transfer most of the work to the centralized control center to reduce dangerous positions and avoid frequent walking on the ground.

-

Solution

3D visualization security management platform, etc.

-

Solutions

-

Products

-

About us

-

Contact Us

sales1@intellicrane.com-

WeChat Official Account

-

Customer Service Account

-