Intellicrane Roter Controller

IRC1 is an intelligent rotor controller with the function of protecting and controlling crane motor. IRC1 series products are used for disconnection and connection control of three-phase asynchronous wire-wound resistors. Through hardware, software and services, it ensures the safe and stable operation of production equipment, realizes efficient production and digital management, making it easier to use .

Features

PRODUCT

-

Reliable equipment improves production saftyReliable equipment improves production saftyIRC1 is dust-free and durable equipment, maximum applicable to 120 degrees ambient temperature, maximum at 60 degrees ambient temperature without capacity reduction.

Accurate and reliable software model, under the precise control of both time and frequency principles, prevents excessive motor rotor resistance switching current shocks, reduces mechanical shocks, and extends the lifespan of motors, resistors, and mechanical systems. -

Easily operated and convenient maintenanceEasily operated and convenient maintenancePlug-and-play portable display panel with key operation and friendly interaction;

Modular design to reduce spare parts cost and conveniently carry out equipment maintenance. -

Digitalization protects production safetyDigitalization protects production safetySuperior master-slave control performance, streamlined control structure to achieve cooperative alarm and fault prediction, to ensure safe and efficient production.

The equipment status is transmitted to the cloud in real time, which enables real-time online monitoring of production equipment.

The system proactively pushes fault information and maintenance advice to prevent sudden equipment failures and losses before they happen. -

Energy saving and environmental protectionEnergy saving and environmental protectionThyristor control technology triggered by pulse transformer without energy consumption.

Simple product design, reducing waste of resources and environmental pollution.

Product quality assurance, longer lifespan, fewer failures, less replacement of spare parts, and resource saving.

Specifications

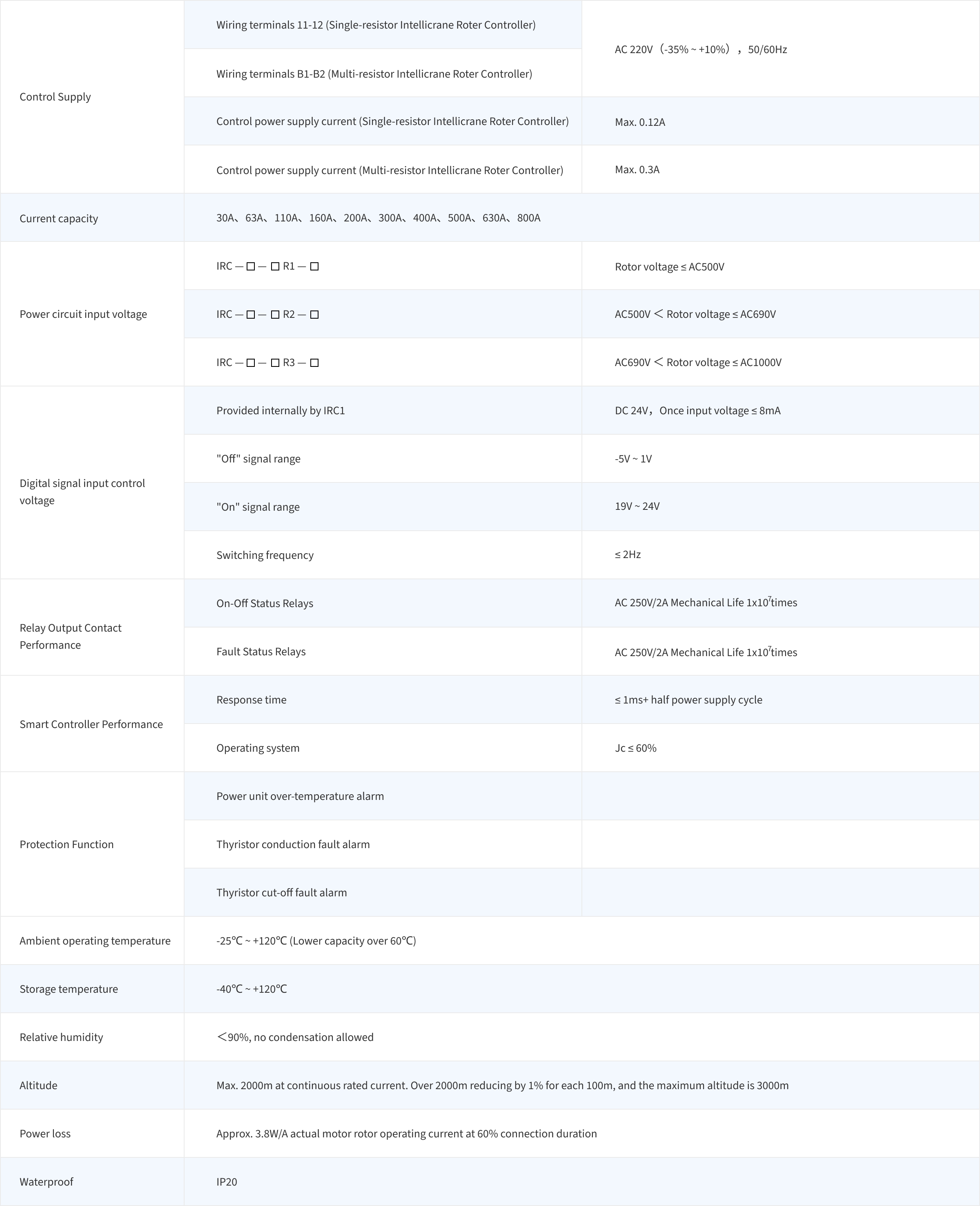

Technical

|

Control Supply

|

Wiring terminals 11-12 (Single-resistor Intellicrane Roter Controller)

|

AC 220V(-35%~+10%),50/60Hz

|

|

Wiring terminals B1-B2 (Multi-resistor Intellicrane Roter Controller)

|

||

|

Control power supply current (Single-resistor Intellicrane Roter Controller)

|

Max. 0.12A

|

|

|

Control power supply current (Multi-resistor Intellicrane Roter Controller)

|

Max. 0.3A

|

|

|

Current capacity

|

30A、63A、110A、160A、200A、300A、400A、500A、630A、800A

|

|

|

Power circuit input voltage

|

IRC — — R1 —

|

Rotor voltage ≤ AC500V

|

|

IRC — — R2 —

|

AC500V < Rotor voltage ≤ AC690V

|

|

|

IRC — — R3 —

|

AC690V < Rotor voltage ≤ AC1000V

|

|

|

Digital signal input control voltage

|

Provided internally by IRC1

|

DC 24V,Once input voltage ≤ 8mA

|

|

"Off" signal range

|

-5V~1V

|

|

|

"On" signal range

|

19V~24V

|

|

|

Switching frequency

|

≤ 2Hz

|

|

|

Relay Output Contact Performance

|

On-Off Status Relays

|

AC 250V/2A Mechanical Life 1x10⁷ times

|

|

Fault Status Relays

|

AC 250V/2A Mechanical Life 1x10⁷ times

|

|

|

Smart Controller Performance

|

Response time

|

≤ 1ms+ half power supply cycle

|

|

Operating system

|

Jc ≤ 60%

|

|

|

Protection Function

|

Power unit over-temperature alarm

|

|

|

Thyristor conduction fault alarm

|

||

|

Thyristor cut-off fault alarm

|

||

|

Ambient operating temperature

|

-25℃~+120℃ (Lower capacity over 60℃)

|

|

|

Storage temperature

|

-40℃~+120℃

|

|

|

Relative humidity

|

<90%, no condensation allowed

|

|

|

Altitude

|

Max. 2000m at continuous rated current.

Over 2000m reducing by 1% for each 100m, and the maximum altitude is 3000m. |

|

|

Power loss

|

Approx. 3.8W/A actual motor rotor operating current at 60% connection duration

|

|

|

Waterproof

|

IP20

|

|

-

Solutions

-

Products

-

About us

-

Contact Us

sales1@intellicrane.com-

WeChat Official Account

-

Customer Service Account

-

Copyright © 2023 盈泰利华. All Rights Reserved. 粤ICP备10203972号-2